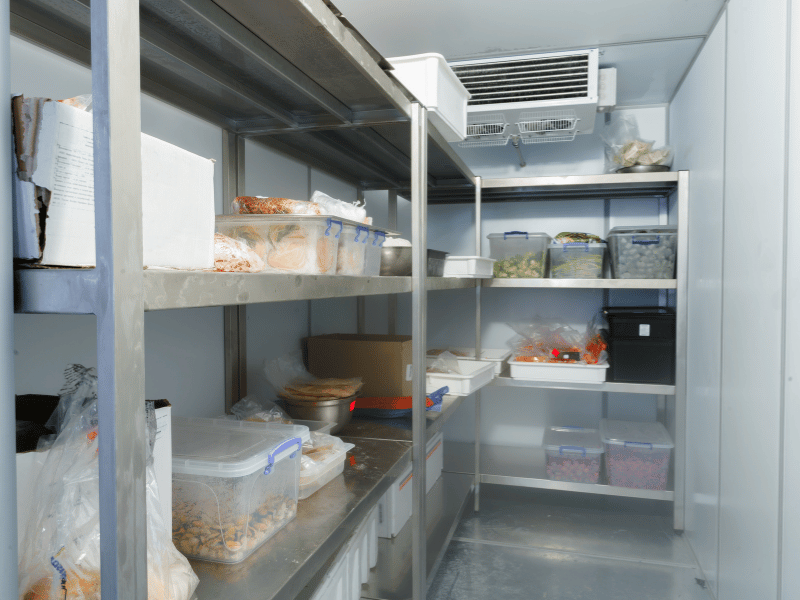

For any commercial kitchen or foodservice operation, refrigeration is the backbone of food safety. From walk-in coolers to reach-ins and display cases, reliable refrigeration ensures food is stored at safe temperatures, preventing spoilage and keeping customers healthy. But reliability doesn’t happen by accident — it’s the result of planned maintenance.

Here’s how a proactive refrigeration maintenance program directly supports food safety and compliance:

1. Maintain Proper Temperature Control

The FDA Food Code and local health departments require strict cold-holding standards to prevent bacterial growth. Even a small variation in temperature can put food at risk. Planned maintenance helps to ensure thermostats, compressors, and refrigerant levels are working correctly so your units consistently maintain safe temperatures.

2. Reduce Spoilage and Waste

A failing gasket or dirty condenser coil may not cause an immediate breakdown, but it can reduce efficiency and compromise storage conditions. Over time, that leads to spoiled food and wasted inventory. With regular inspections and cleanings, these issues are identified and corrected before they cause costly losses.

3. Stay Compliant With Health Regulations

Food safety inspections are non-negotiable. A malfunctioning cooler or evidence of improper food storage can lead to citations, fines, or even closures. Planned maintenance helps operators stay compliant and confident when inspectors arrive.

4. Extend Equipment Lifespan

Food safety isn’t just about the here and now — it’s about ensuring your equipment lasts through years of service. Preventive care reduces wear and tear, helps avoid major component failures, and gives you more predictable performance across your entire refrigeration fleet.

5. Protect Your Brand and Customers

Customers trust that the food you serve is safe. A single foodborne illness outbreak linked to improper storage can harm your reputation permanently. By investing in planned maintenance, you’re protecting not only your customers but also your brand image.

What Planned Maintenance Includes

A refrigeration planned maintenance program with Joe Warren & Sons typically covers:

- Cleaning condenser and evaporator coils

- Checking and adjusting thermostats

- Inspecting door seals and gaskets

- Monitoring refrigerant levels and pressures

- Verifying defrost cycles

- Testing safety controls

This structured approach provides peace of mind that your equipment is performing at its best and that your food safety standards are protected.

Conclusion: Food safety is non-negotiable in the foodservice industry, and refrigeration planned maintenance is your frontline defense. By partnering with Joe Warren & Sons, you gain expert technicians who understand the critical role refrigeration plays in compliance, efficiency, and customer trust.

Don’t leave food safety to chance. Contact Joe Warren & Sons today to enroll in a planned maintenance program and protect your business year-round.