In the food service industry, downtime is more than an inconvenience—it’s lost revenue, wasted product, and frustrated customers. While emergency repairs are sometimes unavoidable, the vast majority of costly breakdowns can be prevented through Planned Maintenance (PM).

The Real Cost of Downtime

Consider a busy university dining hall: if a combi oven fails during lunch prep, not only is service disrupted, but staff must scramble to adapt menus, and potential food waste increases. The repair bill is just one part of the total cost—lost trust and reduced efficiency are harder to measure.

How PM Saves Time and Money

Planned maintenance identifies small issues before they escalate. For example:

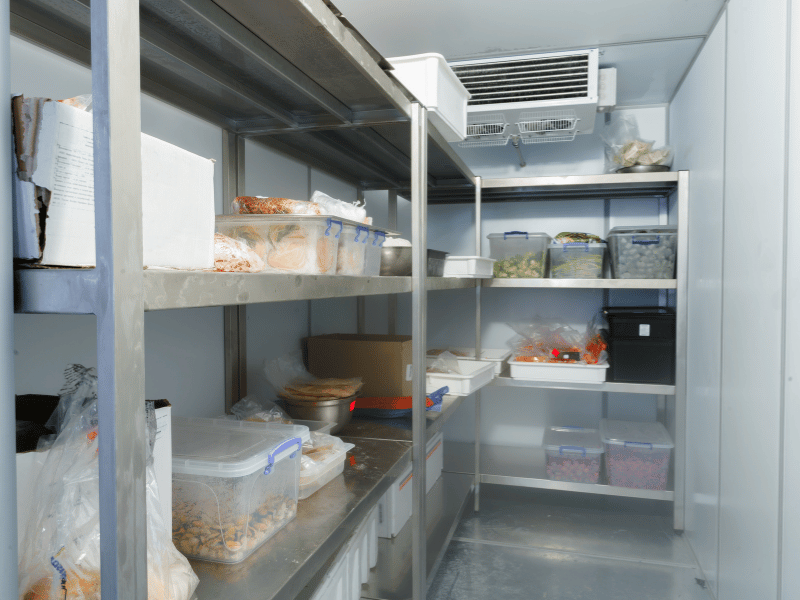

- Case Study 1: A small refrigerant leak in a walk-in was detected during a PM visit, repaired for under $1,500. Left unchecked, it would have led to a compressor failure costing over $5,000 and days of downtime.

- Case Study 2: Preventive cleaning of a combi oven’s steam generator avoided a scale-related heating failure during a high-volume week, saving both repair costs and lost sales.

Customizing a PM Schedule

Every kitchen is different. Joe Warren & Sons works with clients to create PM schedules based on usage patterns, equipment type, and seasonal demands. This can mean quarterly visits for high-use equipment, or bi-annual service for lighter-use appliances.

Additional Benefits

- Improved energy efficiency

- Extended equipment lifespan

- Safer, more consistent performance

- Compliance with health and safety codes

When compared to the cost of unexpected breakdowns, PM is one of the smartest investments you can make for your operation.