Summer is prime time for food service—but it also puts serious stress on your kitchen equipment. Heat, humidity, and heavy usage can push appliances past their limit, leading to costly repairs, downtime, and unhappy customers.

Let’s break down (no pun intended) the top 5 commercial kitchen failures we see in summer—and how you can avoid them:

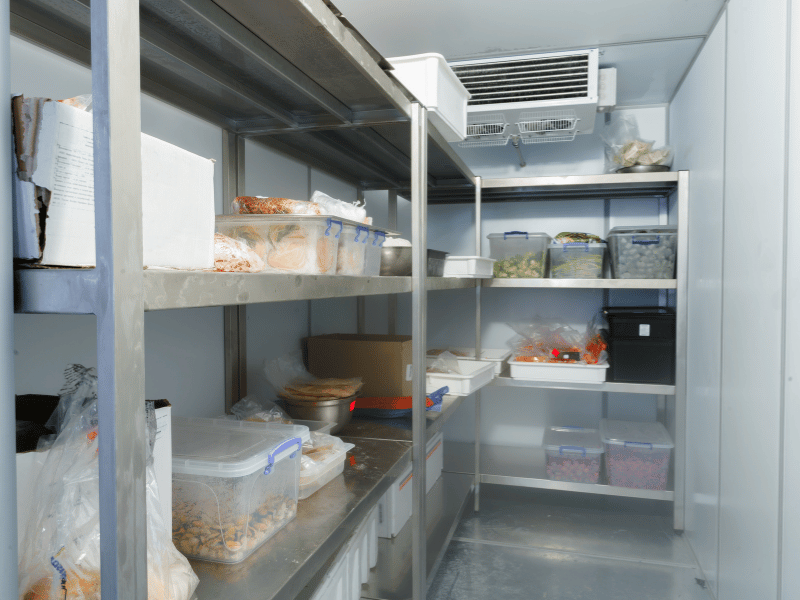

1. Refrigeration Breakdown

Summer heat causes compressors and condensers to work overtime. Poor ventilation and dirty coils are often the culprit.

Prevention Tip:

Schedule seasonal maintenance. Clean coils, check refrigerant levels, and make sure equipment isn’t pushed against walls or blocked by boxes.

2. Ice Machine Failure

This is a summer classic. Without regular cleaning and filter replacement, machines can’t keep up with demand.

Prevention Tip:

Implement a monthly cleaning and maintenance plan before summer hits.

3. Grease Trap Overflows

Grease traps accumulate faster during peak season. Summer’s heat can make smells worse and speed up clogs.

Prevention Tip:

Clean grease traps more frequently during summer months. Don’t wait until there’s a backup.

4. HVAC Malfunctions

Heat in the kitchen affects everything—staff performance, food safety, and even how long your appliances last.

Prevention Tip:

Clean HVAC filters regularly and have your unit serviced before the hot weather hits.

5. Dish Machine Downtime

Hotter kitchens mean higher evaporation and harder water. Dish machines may fail from scale buildup or overheating.

Prevention Tip:

Descale regularly and monitor rinse temperatures. Use manufacturer-approved cleaning agents.

Don’t Let Summer Slow You Down

Joe Warren & Sons offers planned maintenance programs designed to keep your kitchen running year-round. Don’t wait until it breaks—fix it before it fails. Contact us today.