Winter in New England brings more than snow and ice — it brings unique challenges for commercial refrigeration systems. While many operators assume colder outdoor temperatures make refrigeration easier, the reality is that freezing conditions can create serious performance issues if systems aren’t properly maintained and adjusted.

Understanding how cold weather affects your equipment can help prevent breakdowns, protect inventory, and avoid costly emergency repairs during the winter months.

Cold Weather Doesn’t Mean Less Stress on Equipment

Commercial refrigeration systems are designed to operate within specific temperature ranges. When outdoor temperatures drop significantly, components such as compressors, condenser coils, and refrigerant systems can behave unpredictably.

For example, refrigerant pressure can drop too low in extreme cold, causing improper lubrication inside the compressor. Without adequate lubrication, internal components experience increased wear, shortening the lifespan of the system.

Condenser Issues in Freezing Conditions

Air-cooled condensers are especially vulnerable during winter. Snow buildup, ice formation, and freezing rain can restrict airflow, forcing systems to work harder than intended. Poor airflow leads to inefficient heat rejection, even in cold weather.

Additionally, when fans cycle incorrectly due to low ambient temperatures, systems may short-cycle — turning on and off frequently — which puts unnecessary stress on electrical components and motors.

Frozen Drain Lines and Evaporators

One of the most common winter refrigeration issues involves frozen condensate drain lines. When drain lines freeze, water backs up into evaporator pans and can spill onto floors or freeze inside the unit itself. This not only creates safety hazards but can also lead to corrosion and electrical damage.

Ice buildup on evaporator coils is another frequent winter concern. Improper defrost cycles or humidity fluctuations can cause ice accumulation that restricts airflow, reduces cooling efficiency, and increases energy consumption.

Door Seals and Heat Loss

Cold weather makes gaskets brittle. Damaged or stiff door seals allow warm air to enter refrigerated spaces, forcing equipment to run longer to maintain set temperatures. This constant cycling increases wear on compressors and drives up energy costs — even when outdoor temperatures are low.

Regular inspection of door gaskets during winter is essential to maintaining consistent internal temperatures and preventing unnecessary strain on systems.

Power Fluctuations and Winter Storms

Winter storms often bring power outages or voltage fluctuations. Even brief interruptions can damage sensitive electronic controls in modern refrigeration systems. Without proper surge protection or backup planning, facilities risk sudden failures that jeopardize stored food and inventory.

Why Winter Maintenance Matters

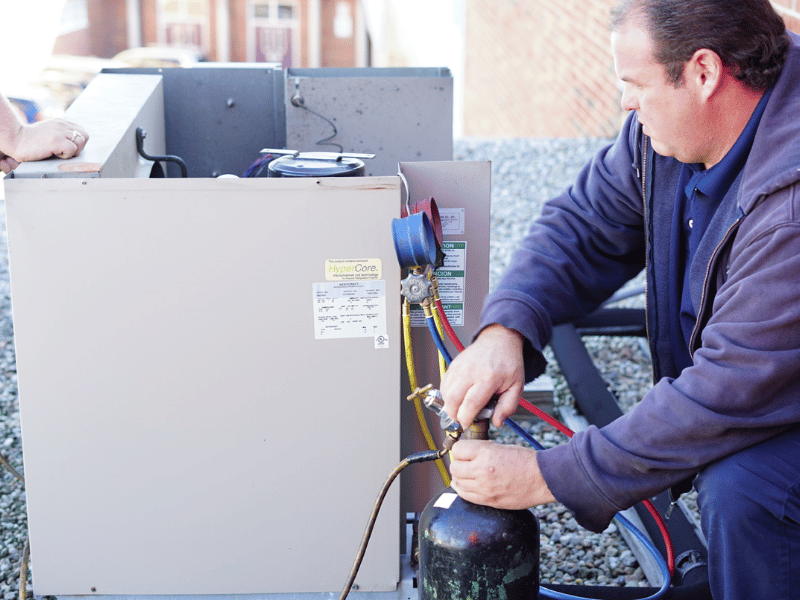

Planned winter maintenance helps technicians:

- Adjust systems for low ambient operation

- Inspect and clear condensers

- Prevent frozen drain lines

- Verify proper defrost cycles

- Identify early signs of component wear

Addressing these issues proactively keeps systems running efficiently and prevents emergency calls during the busiest or most inconvenient times.

The Bottom Line

Freezing temperatures don’t reduce the need for refrigeration maintenance — they increase it. Some commercial refrigeration systems require seasonal adjustments and close monitoring to operate reliably through winter.

With proper maintenance and professional oversight, businesses can avoid winter-related failures and ensure their refrigeration equipment is ready to perform year-round.